Direct Thermal vs. Thermal Transfer

The Best Label for your Application

Do you know which label you’re currently using? Try the scratch test!

Run your thumbnail across your label quickly (as if striking a match) a couple of times. Is there a dark mark on your label? Then you are using a direct thermal label. If not, your label is a thermal transfer label. You can try other heat methods to test which label you have as well.

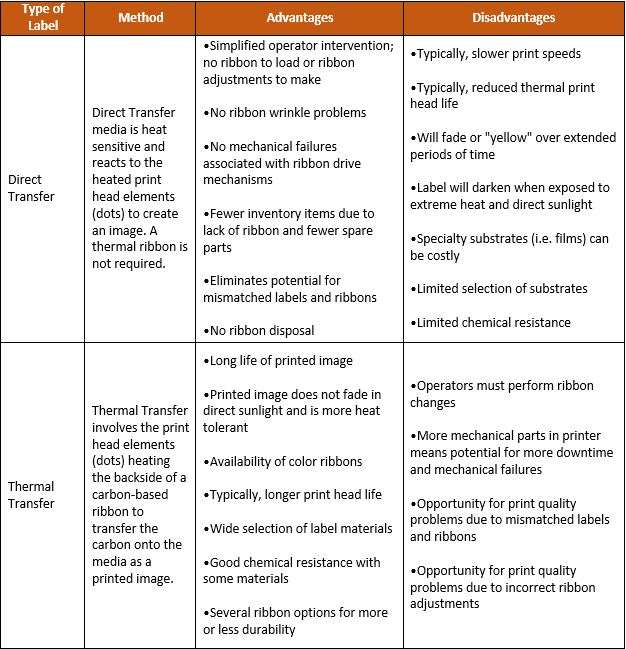

The differences between these two types of labels can be summed up as follows:

Direct Thermal (DT) Labels:

- Require a DT printer

- No ribbon

- Typically black print

- Fades with time

- Paper labels only

- Economical

- Generally used in simpler applications

Thermal Transfer (TT) Labels:

- Require a ribbon printer

- Printable on various label substrates, including:

- Paper

- PVC

- Vinyl

- Nylon

- and more

- Can be constructed to resist:

- UV rays

- Chemicals

- Abrasives

- Substrates and adhesives specifics drive price

- Used in a wide range of applications

Choosing the Best Label for your Application